3D PRINTED ORTHOGNATHIC SOLUTIONS

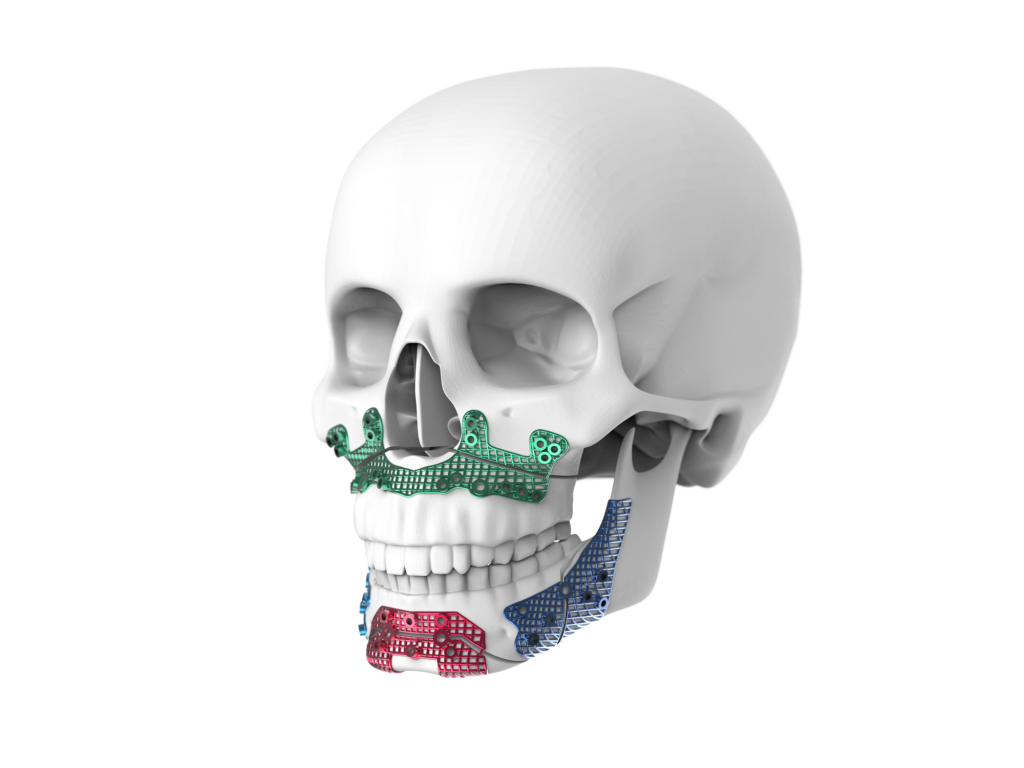

3D printing technology has made significant advancements in the field of medicine and dentistry. Orthognathic procedures involve correcting abnormalities in the jaw and facial bones to improve a patient’s bite, facial appearance and overall oral health. 3D printed plates and surgical guides have become valuable tools for planning and executing these procedures more accurately and efficiently.

We work closely with our partner Personalised Surgery to deliver tailored patient-specific implants and instruments (PSI) tailored to suit the needs of every case. Our comprehensive service encompasses Virtual Surgery Planning (VSP) by skilled Australian engineers,local design and manufacturing, a user-friendly online app for streamlined case management, and cutting-edge grafting solutions that optimise fixation. This includes product thickness, screw angulation, surface finish, etc

Key Features of our Orthognathic Solutions

Australian Designed and Manufactured: Our products are proudly Australian designed and manufactured, guaranteeing precision, quality, and compliance with the highest international standards. The result is a line of products tailored specifically to your patient needs, ensuring optimum outcomes for your patients.

Quick Turnaround Time: Recognising the urgency often associated with surgical procedures, our streamlined processes and efficient manufacturing allow for rapid turnaround times, facilitating your surgical planning and patient care.

Comprehensive Support: Our commitment extends beyond the products themselves. We provide you with comprehensive support and professional services, ensuring that your experience is seamless and rewarding.

Patient-Specific Models: Before the surgery, patient’s CT or MRI scans are used to create a 3D model to allow the surgeon to visualise the patient’s specific anatomy in detail.

Virtual Surgery Planning (VSP): using specialised software surgeons can simulate the planned orthognathic procedure on 3D models. This includes repositioning the jawbones to achieve the desired outcome. The use of VSP enables precise planning and visualisation.

Custom Surgical Guides: Based on the VSP, custom surgical guides and templates are 3D printed. These guides aid the surgeon during the procedure by indicating the exact position of bone cuts and plate placements. This provides accurate execution of the procedure.

Patient-Specific Plates: 3D printing is also used to create patient-specific plates that will be screwed into stabilise the repositioned bones. These plates are designed to fit the patient’s anatomy perfectly, reducing the need for intraoperative adjustments.

Reduced Surgery Time: With the aid of 3D printed guides and plates, orthognathic surgery becomes more efficient leading to reduced surgery time.

Improved Surgical Outcomes: The precision of the pre-planning and 3D printed guides and plates leads to more accurate surgical outcomes for patients.

Our local engineering also allows us to offer a personlised approach to each case, providing the best solutions for the best patient outcomes. The engineers work directly with surgeons. which provides a quality product with superior outcomes for the patient. Local manufacturing also provides shorter turn-around times.

Compared to traditional surgical techniques, the use of VSP and PSI are demonstrated to improve surgical accuracy, In addition, these approaches have shown to reduce the planning and theatre time and intraoperative complications. Our CMF Orthognathic services provide improved bone fixation stability and an overall superior patient consultation experience.

To view the brochure please click here